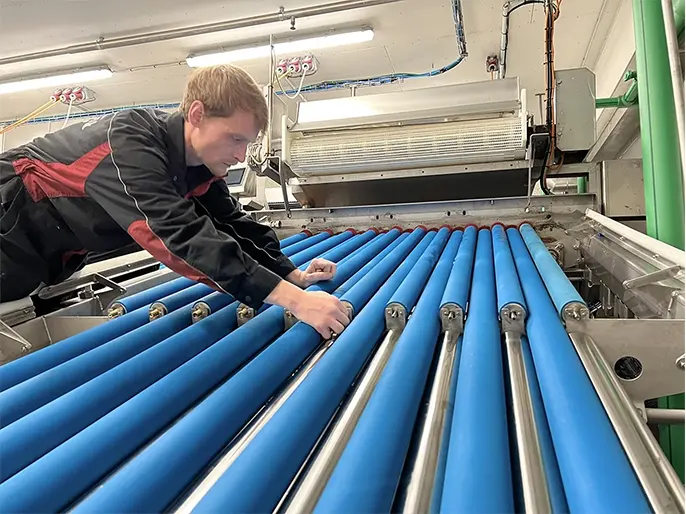

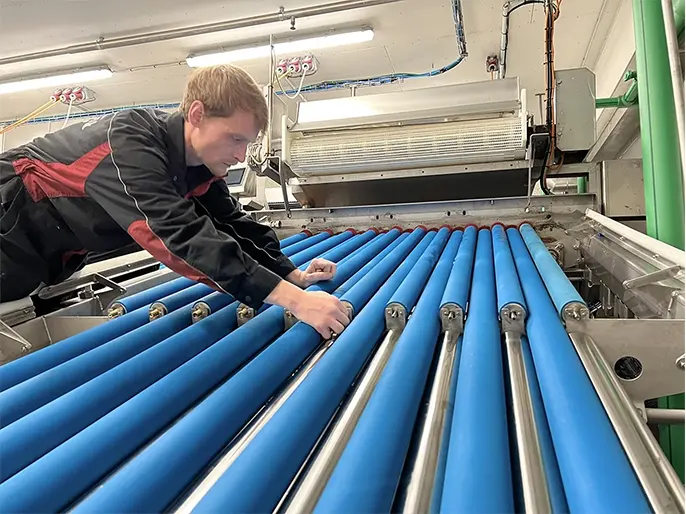

Martak roller maintenance

20 April 2022

Møre than just longline

26 August 2022

Martak roller maintenance

20 April 2022

Møre than just longline

26 August 2022Why frozen food reduces carbon footprint?

Shrimp processing machinery from Martak protects the product during the processing stages and delivers high-quality, nutritious shrimp ready for the consumer.

Roughly one-third of food produced worldwide for human consumption gets lost or wasted. Fresh food, organic products, fruits, and vegetables have the highest wastage rates of any food. Large quantities of food are wasted at the retail level due to quality standards that over-emphasize appearance.

The best way to reduce food waste is to freeze it

during fishing or farming, transportation, and preparing dinner at home. As fresh food goes bad overtime in the household and goes into the trash, the frozen food can be stored for months, taken in quantities that are needed.

The shrimp glazing machine protects the product and maintains moisture and nutrients.

Is fresh food always the freshest?

Storage buffer from Martak keeps the shrimp frozen after the processing until packaging.

Seafood produce sold “fresh” can be over two weeks old, depending on the distribution chain. In comparison, frozen seafood is caught at its peak of quality and frozen within 4-8hours. Frozen food can be just as nutritious as fresh food, and freezing produce can retain vitamins better. Taste and texture are unaffected by the freezing process, while the “fresh” produce loses its vitamins, appearance, and flavor over time.

We want to make a difference!

We are tackling global food waste and reducing our carbon footprint!

Frozen food plays a crucial part in decreasing the carbon footprint and food waste. Freezing food and offering your clients “perfect portions” can play a vital role in tackling the global issue of food waste and global warming.

Slower transport means reduced carbon footprint.

When produce is frozen, there isn’t the same time pressure as when transporting fresh produce. Using freight vessels rather than air transport significantly reduces carbon footprint.

We are ready for the challenge.

Martak offers one of the best seafood processing machinery globally and a full range of solutions. We offer consultation, designing, set up, training, and we are here for you in the future for general maintenance to help extend your machinery lifetime. We are continuously improving our machinery and expanding our line of machinery with new and innovative designs.

Our line of machinery goes from the first steps of the production line to packaging and is ready to ship to consumers/customers.

We want to do better by offering water and eclectic efficient machinery

Martak’s frozen machinery! We offer machinery for your food processing plant to keep your consumers satisfied with their frozen produce.

The phase shifter from Martak cools the product down below freezing level while saving energy and protecting the shrimp from the blast freezer. Blast freezers are rough and decrease the shrimp quality due to high airflow and dry air.

Smart storage freezer

Smart storage freezer – first in, first out. The smart storage freezer has been developed with the customer’s needs in mind. The major upside is that processing and packaging are not reliant on running simultaneously. This freezer ensures that the first product in is the first product out. The smart storage freezer can be fitted into any processing line. Read more about the smart storage freezer here.

Glazing machines

Glazing machines – protect the product. Ice glazing is an important step in the processing line. Ice glazing can be used for all kinds of produce. The glazing machines apply a protective layer of ice over the already frozen seafood product. Read more about our shrimp glazing machines and fish glazing conveyors here.

Brine system

Brine chilling system provides a fast and uniform heat transfer for food processing. Click the link If you want to learn more about Brine systems, .

Scales

Scales – to provide your consumers perfect portions. Click this link if you want to check more information about our scale solutions.

Packing scales

packaging scale is an important machine to prepare the product for shipping. To read more about the packing scales, please follow this link.

Conveyor belt systems

Scanbelt – a great option for frozen food, hygienic, reliable. Check our conveyor belt solutions here.

Share this post on social networks:

Share this post on social networks: