SHRIMP PROCESSING

Martak’s high-quality shrimp processing machinery results from our long-term experience in the seafood industry. Our focus is to provide tailored machines and solutions to every factory’s needs. We offer a complete line of shrimp processing equipment.

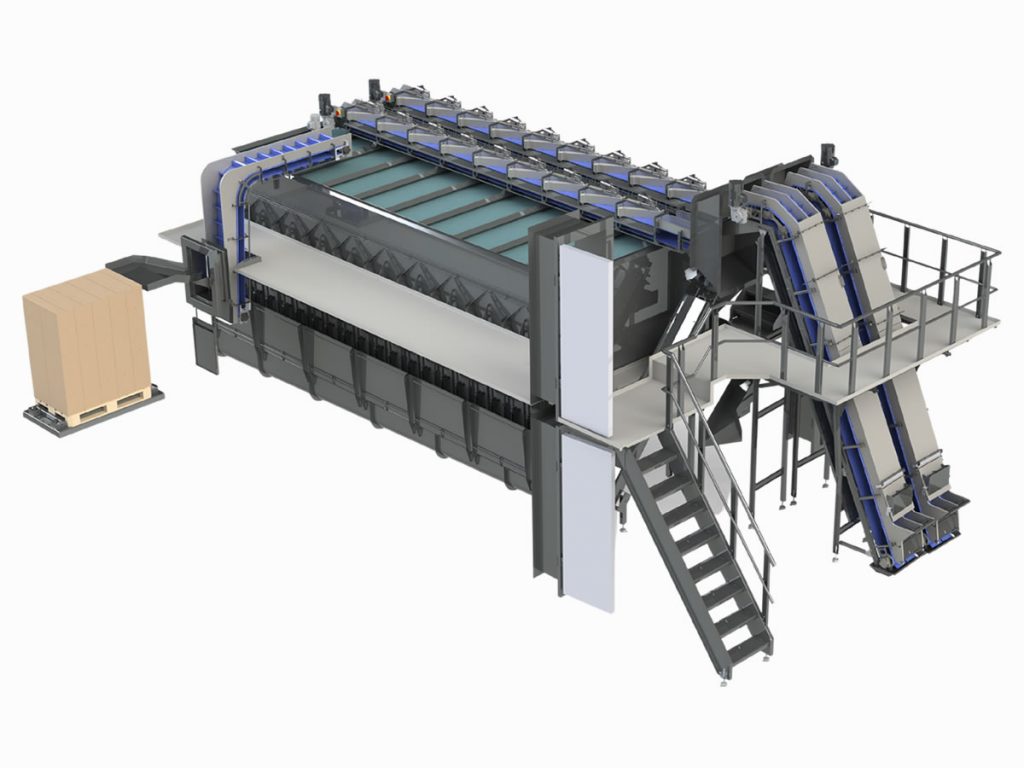

Shrimp ProCooker

Martak’s ProCooker for shrimp combines the last 20 years of industrial cooking innovation into a refined process control tool. ProCooker allows for highly uniform cooking, yield and energy efficiency. The ProCooker has an innovative control system, based on high precision sensors, that ensures an even mixing of steam and uniformity of temperature through each cooking segment. Combined with a robust construction that brings a reliable machine with high accuracy.

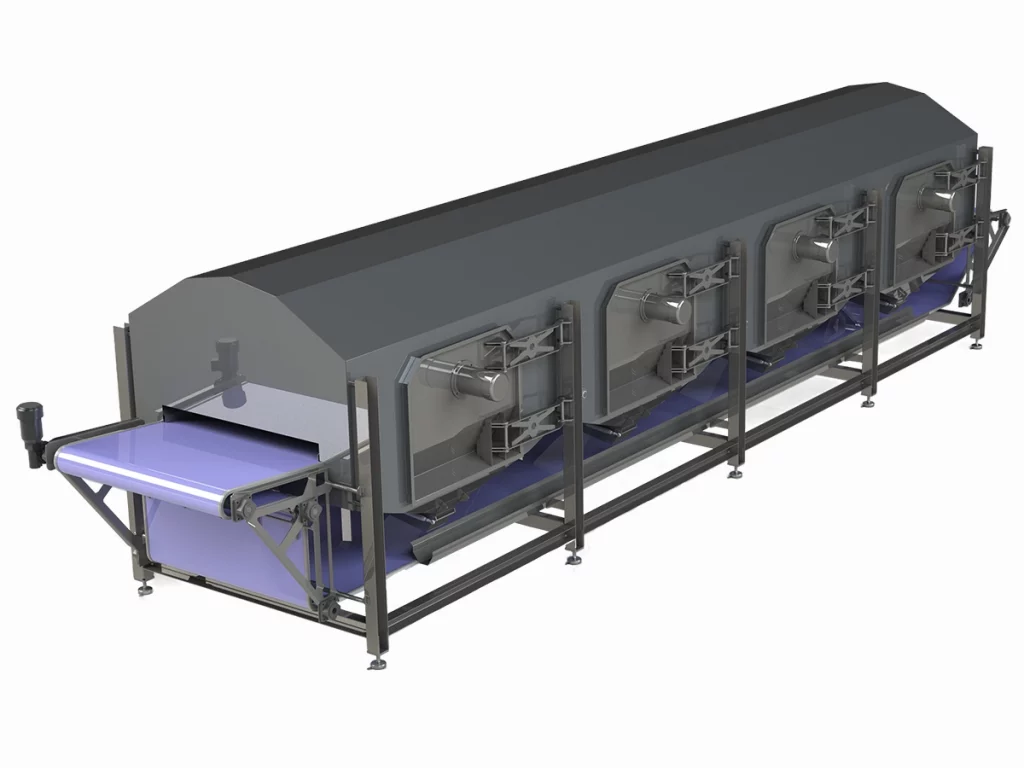

Steam Cooker

Highly effective and economical industrial shrimp steam cooker. After evenly distributing the shrimp into the washbasin, a wave oscillator provides a single layer of shrimp for cooking. Customizable speed and temperature ensure the even cooking of the product. Its hygienic design allows easy access to clean components. The industrial shrimp steam cooker can be fully opened for easy and effective cleaning at the end of the day, and it is customizable to suit your company’s needs.

Shrimp Peelers

Martak has designed shrimp peelers specifically for cold water shrimp. Our most traditional peeler, the “Mar-a” is one of our best sellers and has proven to be reliable, fast, and accurate. Our newest design is a breakthrough in the shrimp industry and saves up to 70% of electricity and 30% of the water used for the machines. We also manufacture a shrimp after peeler that ensures that no shrimp goes unpeeled.

Shell Separators

Our shell-separating blowers have proved their worth as powerful, reliable workhorses in any shrimp or shellfish cleaning needed. Without any pre-drying required, an energy efficient design and low operating costs, our blowers are unmatched by any other solution. All Martak shell separators are designed for safe, hygienic operation and include a variable speed control for fan and conveyor belt along with an air lift hood for easy cleaning. All this while minimizing its footprint, offering several sizes specifically for your needs.

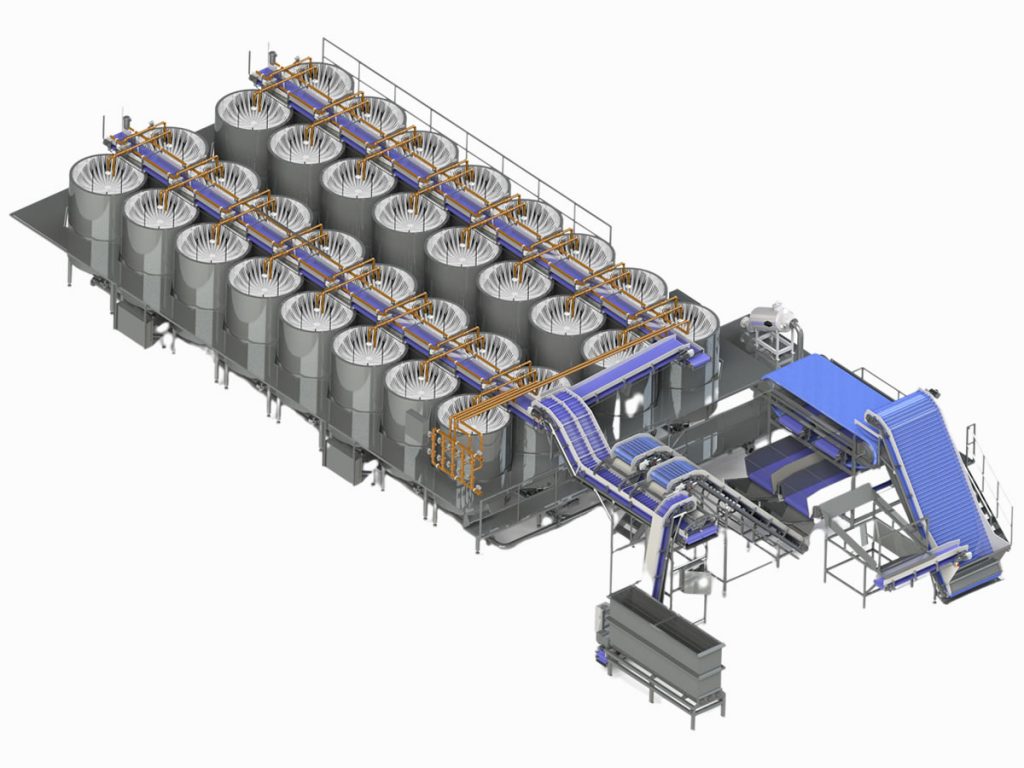

Maturing System

Martak IQ maturing system maintains product quality and gives you control for every batch. Infeed tanks and conveyors distribute an even product flow onto a precise grader that separates the product into size categories. Each category is then put into maturing tanks. Smart monitoring technology gives you the ability to ensure the proper weight of the product in each tank.

Shrimp Washer

Our shrimp washer is made of high-quality stainless steel and meets the food industry standards. The washer is designed with energy efficiency and easy cleaning in mind. The washer is fitted with speed control and rubber wheels™.

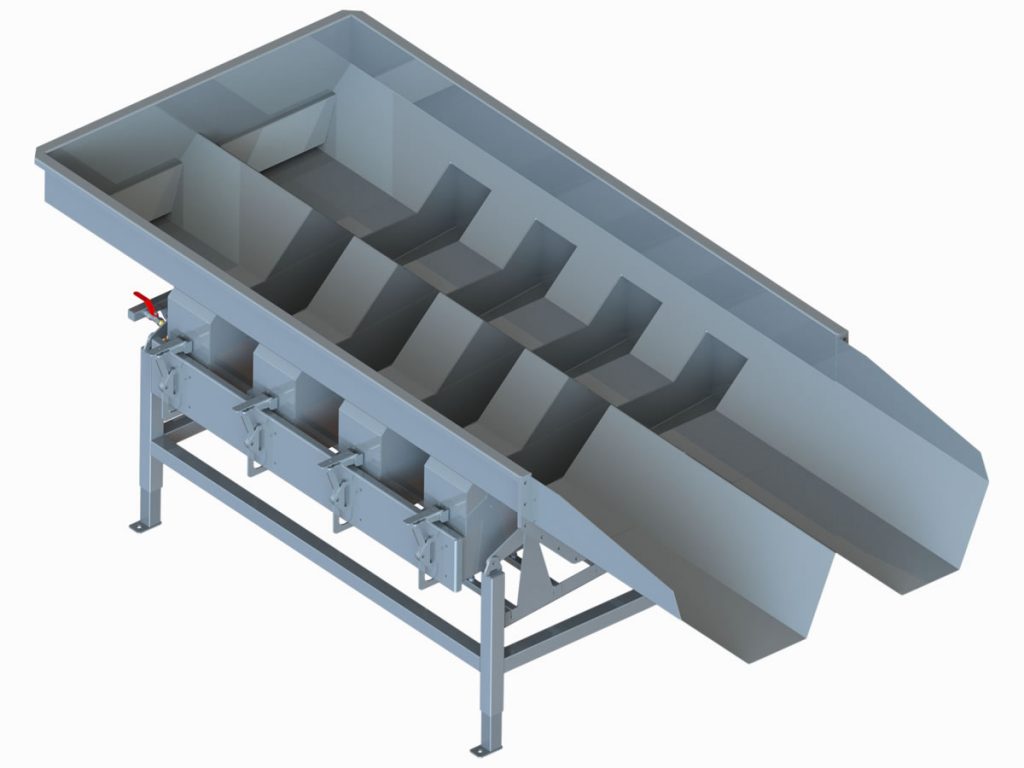

Rock Separator

Our Rock separator is designed to separate rocks from shrimp and other products. Rock separators are commonly used in food processing plants to separate rocks from shrimp and other food products. Once they’ve been separated, the product will continue down the processing line.

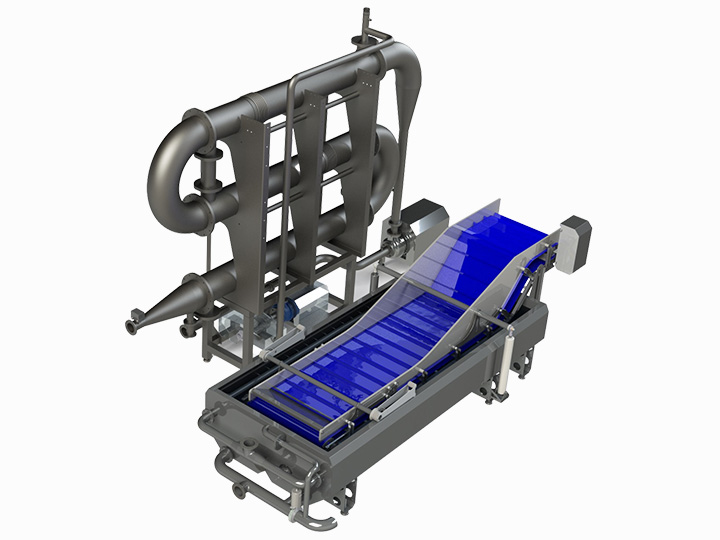

Brine Chilling System

Martak’s signature Brine chilling system provides a fast and uniform heat transfer for food processing. The system’s main components are: a computer screen that monitors the heat from the beginning to the end, four temperate monitoring probes, a conveyor, and a salt melting system. The salt melting system is located at the back of the system and measures the correct amount of salt. The conveyor is programmed to cool the water down to -1degrees (the optimum temperature before the product enters the freezer).

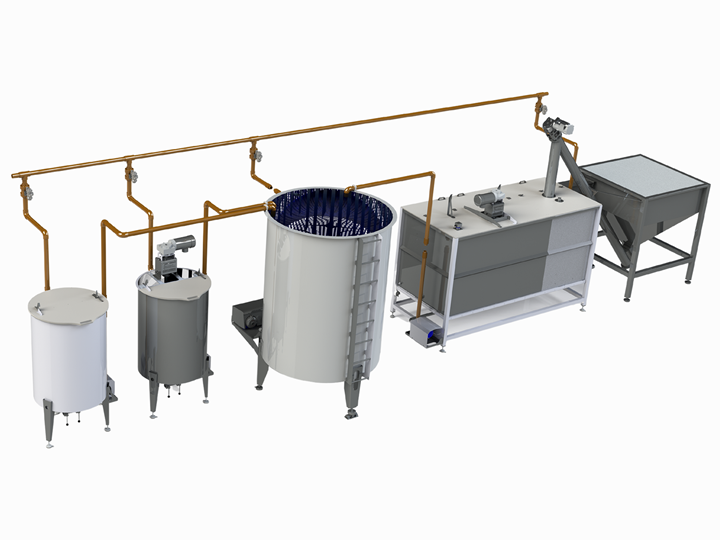

Brine Mixing System

Our complete brine system is available as the complete system or as a stand-alone unit. We offer tailored sizes for each client’s needs. With Martak’s brine system you are equipped with high-quality machinery, designed to mix all additives. From functional ingredients to heavy brines.

Glazing Units

Ice glazing is an important step in the processing line. The glazing machines apply a protective layer of ice over the already frozen seafood product. The glazing machine comes in a standard size and a compact size. The unit lanes can be adjusted by the capacity and the glazing required.

Smart Storage Freezer

The smart storage freezer has been developed with the customer’s needs in mind. The major upside is that processing and packaging are not reliant on running simultaneously. The smart storage freezer can be fitted into any processing line. The freezer is multifunctional and can be used for most products, to mention a few: shrimp, fish, scallop, fruits, vegetables, meat, and more. No matter your production, this freezer ensures that your first product entering the freezer is the first product out (FIFO).

Infeed Tanks

Effectively moving whole shrimp from tubs to conveyors one by one. Our infeed tanks ensure that the product is cleaned, cooled and individually fed into the production line. Optional cleaning conveyors can be added to remove any ice and debris from the tub. Our exceptionally hygienic design allows cleaning staff to lift the entire belt assembly and easily clean the whole tank.

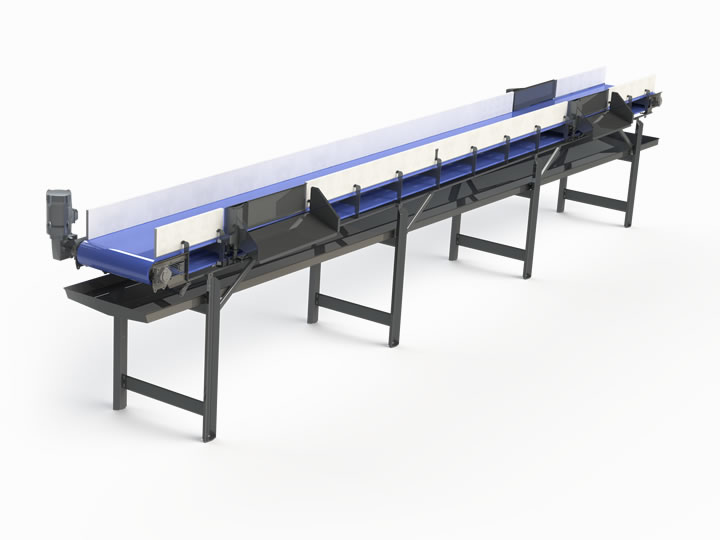

Conveyors

Martak has experience manufacturing many different types of conveyors from belt driven, chain, pneumatic, hydraulic, or screw. We’ve supplied conveyors to many diverse industries.

Conveyors are used to transport goods in bulk for various industries: food, manufacturing, distribution, product handling, and warehousing.

Scales

Martak offers a variety of scales to fit your requirements. Designed with precision, safety, and hygiene for whole fish, fillets, or pieces, you can achieve any level of precision. Take your production line to the next level with our pre made and custom solutions for the fishery industry.

Packing Scales

To complete your processing line, the packaging scale is an important machine to prepare the product for shipping. Martak offers a variety of packing scales that can fit into different processing lines. How the packing scales work: the product is collected in a bin with a weight monitoring system. When the desired weight is reached, the bin input will close, and the output will open, collecting the product into the packaging box. Several arrangements are available with multiple bins.

Packing Tables

A continuous flow of products arrives on the upper conveyor, grabbed by a worker, and put into boxes. The boxes that are then filled with product go on the lower conveyor. With work tables on both sides of the infeed belt and convenient box storage on top, this design maximizes productivity while minimizing the floor space required. Its robust design allows easy cleaning. The packing table can be tailored in height, length, width, and amount of workstations needed.

Packing Scales

To complete your processing line, the packaging scale is an important machine to prepare the product for shipping. Martak offers a variety of packing scales that can fit into different processing lines. How the packing scales work: the product is collected in a bin with a weight monitoring system. When the desired weight is reached, the bin input will close, and the output will open, collecting the product into the packaging box. Several arrangements are available with multiple bins.

Packing Tables

A continuous flow of products arrives on the upper conveyor, grabbed by a worker, and put into boxes. The boxes that are then filled with product go on the lower conveyor. With work tables on both sides of the infeed belt and convenient box storage on top, this design maximizes productivity while minimizing the floor space required. Its robust design allows easy cleaning. The packing table can be tailored in height, length, width, and amount of workstations needed.

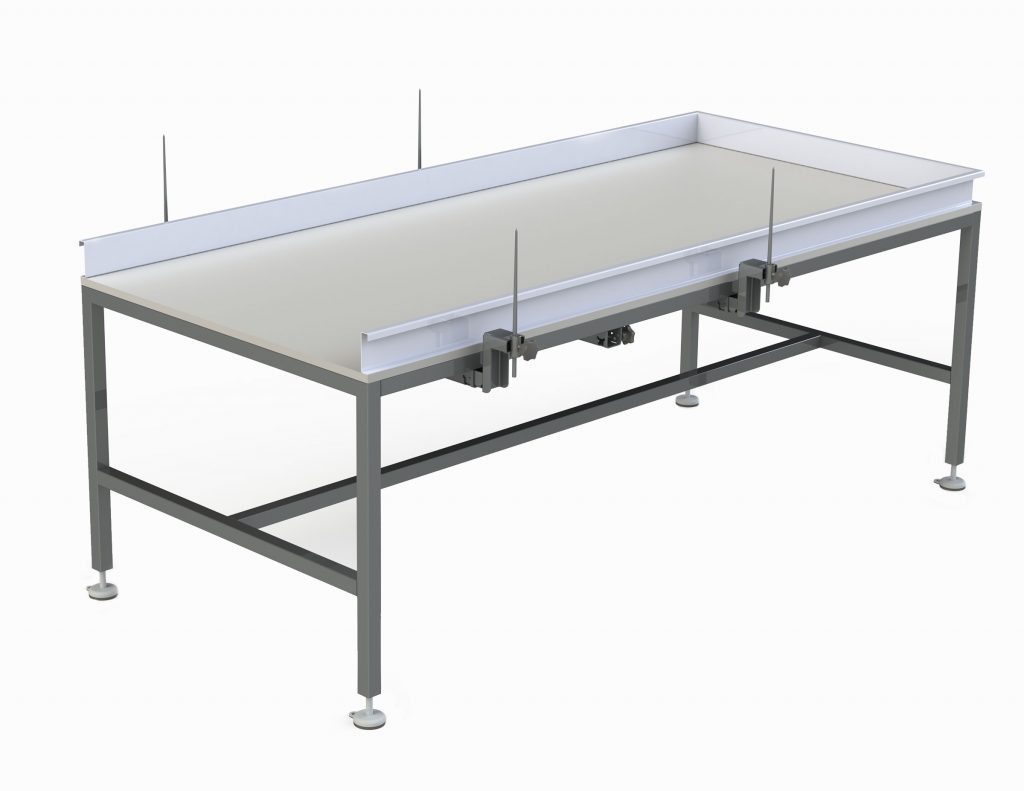

Worktable

Martak designs custom-made work tables for a variety of industries. We offer durable steel frame construction and a tailored design for your needs. Martak work tables can be tailored in height, length, width, amount of workstations needed, and more.